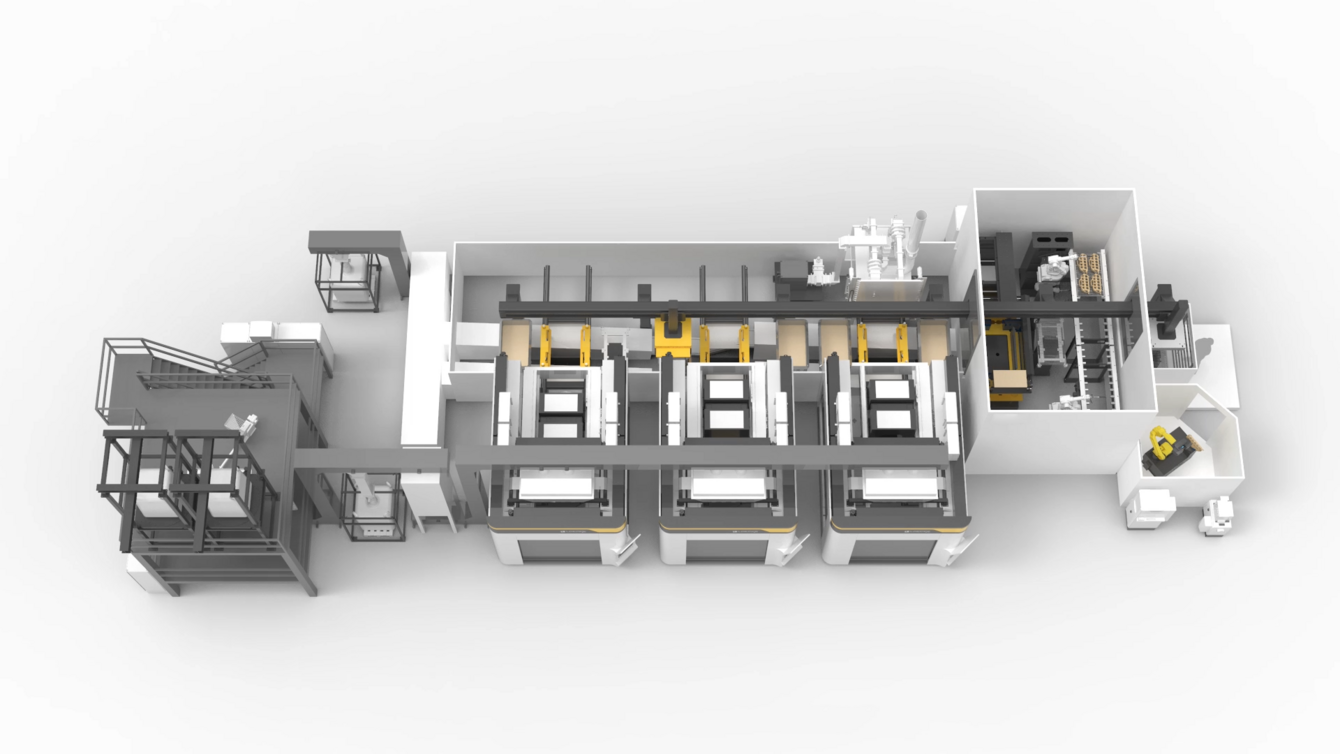

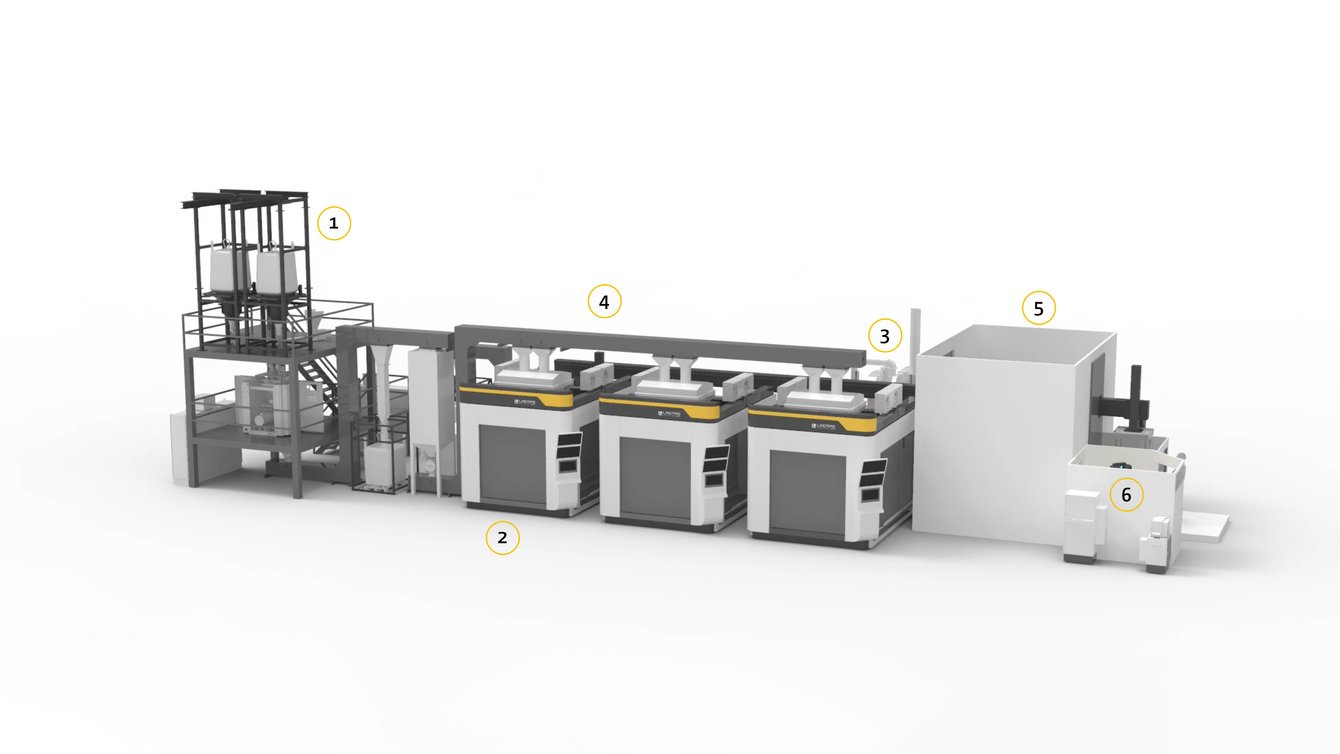

Additive Core Production

Prototype or series production? We design and install your turnkey system for additive manufacturing of your cores - all from a single source. Start with a single printer for your prototypes and expand your system as required according to our modular principle up to fully automated series production of your cores.

1. Moulding material preparation

Depending on your requirements, we install the necessary components for your moulding material preparation. This means storing, conveying and conditioning the sands and additives, mixing the components and transporting the moulding material to the printers. It is also possible to regenerate the excess moulding material from printing and unpacking and return it to the cycle.

2. 3D printing

We develop your printer with organic or inorganic binders customised to your requirements, depending on whether you want to produce prototype cores and small series or ready-to-cast cores in large series. Our powerful software Laempe Printing Wizzard creates the print job based on your CAD data and defines the appropriate printing parameters. Our modular system allows you to start with a single printer and expand your system as required depending on your core production requirements.

3. Microwave curing

For inorganic or organic binder systems that require downstream curing, we develop microwave technology and provide you with the best possible set of parameters for curing.

4. Automatic build box handling

In our automated system, the build boxes are transported to the printers, picked up from there for microwave curing and fed to the desanding area. If required, we can put together a fully interlinked and automated system, including the necessary transport technology, and programme all interfaces ourselves.

5. Automatic core cleaning and quality assurance

Additive core production - without cost-intensive manual labour: On request, your printed cores can be automatically desanded and cleaned. They can then be subjected to optical measurement to fulfil your quality requirements.

6. Control centre and integrated process monitoring

Our control centre takes over the central control of your system, eliminating the need for manual process starts by your employees. At the same time, all relevant sub-processes and material flows are monitored in real time, including the printing process, so that you always have a complete overview of your system.

Hybrid core making

Combine conventional and additive core production: Expand your existing core shop, consisting of core shooters, and achieve a new level of flexibility and process reliability in core production. We integrate 3D printing into your existing core production or create a completely new concept for your hybrid core shop.